If you’re looking to reduce inventory logistics costs, you’ll need to determine the optimal number of units to purchase when it’s time to restock.

Back in 1915, Harris from General Electric introduced a formula to help inventory managers and retailers figure out how much product to buy.

This formula is known as the Economic Order Quantity (EOQ). It’s one of the most important inventory control tools and helps optimize supply chain logistics while keeping costs low.

Here are the assumptions behind the EOQ model:

- Demand is known and constant throughout the year

- All costs (including reorder costs) are known and fixed

- Delivery is instant as soon as the order is placed

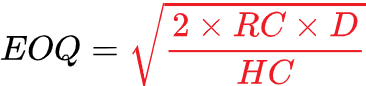

To calculate EOQ, you’ll need the following:

D = demand (total number of units sold annually)

RC = reorder cost (cost of placing each order, including equipment and quality checks)

HC = holding cost (yearly cost of holding one unit, including warehousing and insurance)

Example:

D = 2,000 units/year

RC = $160

HC = $4 per unit/year

The optimal order quantity is 400 units per order.

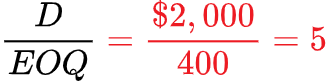

To calculate how many orders you’ll need to place in a year, divide the annual demand by the EOQ. This result is called the period order quantity. Based on the previous example, you’d expect 5 orders per year:

While EOQ doesn’t account for every possible variable, it’s a great way to find the ideal balance of order size and frequency for a given demand level. It can help you save money, boost profits, and streamline your inventory.

Download our economic order quantity (EOQ) Excel template for free. Try it with your own numbers or explore the examples included.

To learn more about EOQ, visit: Investopedia — The evolution of accounting.